Share This Article

Polly Polymer opens a “dark factory”

Chinese company Polly Polymer made a round of financing, as a result of which it raised $15.5 million. The main investor was Vitalbridge.

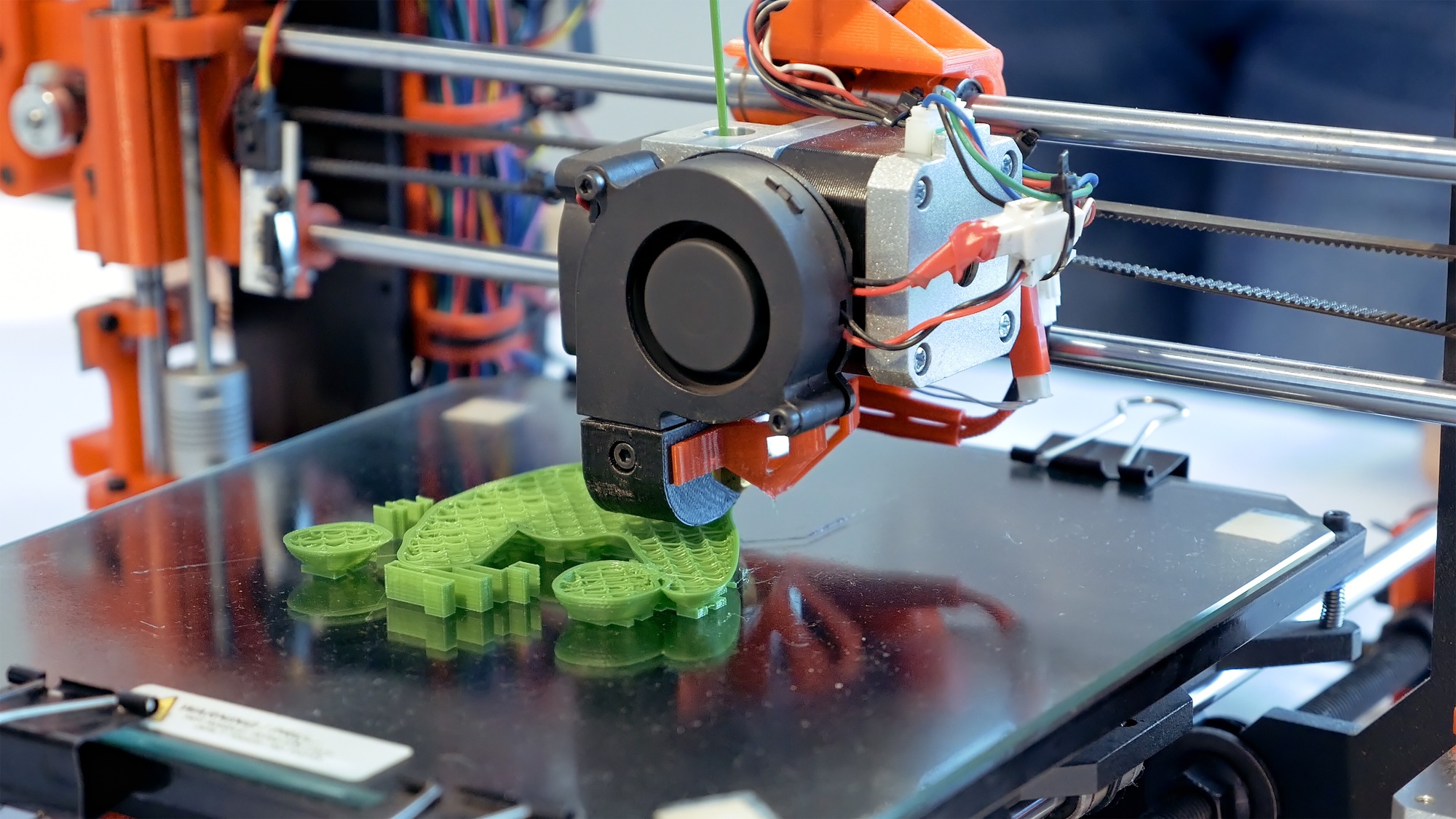

The startup is engaged in the development of 3D-printing technology using the SLA method. Polly Polymer plans to use the funds to put into operation the so-called “dark factory”. It is already under construction in Anhui province. The factory will operate in unmanned mode and will not require lighting. All production processes will be fully automated thanks to the introduction of cloud solutions. The factory will be able to print at high speed and on a large scale. For example, using a 3D printer, the soles for 10,000 pairs of shoes can be printed in just one day, and everything will be automated. In addition, Polly Polymer intends to quickly expand its capacity by replicating industrial lines if necessary.

Printing speed is important for many manufacturers, as can be seen in the example of the same shoes. When a new model is released, a large company makes about 40 sizes, including 22 sizes for children, 8 for women and 10 for men. In the case of athletic shoes, there are also width options, usually four grades. This means that to produce just one model, more than 90 kinds of metal molds must first be created. Making the latter takes about 30 days. In addition, shoe design, trial production extends this period to 2 months.

Polly Polymer’s technology makes it possible to significantly reduce the preparation time and the production process itself. All data is synchronized in the cloud and sent to the printer.

The Chinese startup uses SLA or laser stereolithography technology, which is based on the principle of layer-by-layer solidification of liquid material under the influence of a laser. This solution is used for 3D printing on an industrial scale, and is one of the first in the world. Despite the fact that SLA has been used for 3D printers for a long time, it remains one of the most precise options for production. The material used in this manufacturing method is polymer resin, which is taken in liquid form, and during the printing process it hardens into the originally specified shape. After the formation of the object is completed, it is placed in a container with a special composition to remove excess parts. Then another laser beam exposure takes place, which reinforces the curing. It should be noted that SLA is applicable not only for shoe production, it is also used in the aviation industry and medicine.

In addition to high-speed 3D printing, Polly Polymer provides services for developing special materials and creating special equipment and software. The company is focused on corporate clients.